Logistics Sustainable or Green

The “Green and Sustainable Logistics” has as main objective to meet the principles of environmental sustainability, considering the responsibility of the “cradle to grave” or “cradle to cradle”. Responsibility of the “cradle to grave”, who produce should also be responsible for the final destination of the products generated in order to reduce the environmental impact they cause, incinerating them or arranging them in sanitary landfill.

However, since there are criticisms of this model, which has been gradually replaced by responsibility “cradle to cradle”, which proposes that society continues to consume and develop, but instead of destroying the environment, must feed the biological cycle of the Earth (junk = food) and the cycle of technological industries. In this context, it can not be used as a nutrient / food to the environment must be broken down into elements that can be absorbed by the industry as raw materials quality.

The concept proposed by McDonough and Braungart and called “Cradle to Cradle” concept assumes that the management of the life cycle from cradle to grave can no longer be considered economically viable and environmentally is much less efficient, since it is nitório many residues have possibilities for upgrading and rehabilitation in production processes and / or business and should not simply be incinerated or disposed of in a landfill.

Moreover, logistics management focuses on the integration of company activities, because considering that all these activities are part of a single process, whose goal is to satisfy the needs of the end client, there is no reason to manage them separately incurring unnecessary risks to the company.

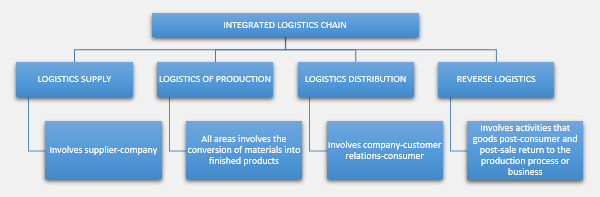

In turn , the integrated logistics chain has basically four areas: logistics supply , production logistics , distribution logistics and , more recently , reverse logistics , as the figure demonstrates . Each of these sub – areas includes differently the environmental variable in its processes.

As seen in the figure, each of these areas has a specific function and paramount in creating value for customers and jointly seek the alignment of business processes in each environmental variable can be inserted in traditional activities, as described below.

Logistics or supply input ( inbound ) is the operationalization of the relationship between the company (client ) and their suppliers of products or services . Under the environmental aspect is in this sub – area that fall within the activities of selecting suppliers and sustainable procurement , which began to consider appropriate indicators for this purpose , which can be cited:

- Using a life cycle analysis to assess the environmental impact of products and packaging.

- Existence of objectives attached to the reduction of waste generation.

- Participation in reverse logistics projects (disposal, collection, reuse, recycle).

- Reverse Logistics Programs.

- Consumption of energy and water.

- Gas emissions and pollution reduction.

- Planning and environmental policies.

- Certificates ISO 14001.

- Clean technologies available.

- Use of environmentally friendly materials and packaging.

- Use of fleet vehicles powered by bio – fuels , alternative energy and hybrid electric.

In turn, the logistics of manufacturing and manages all resources areas in the conversion of materials into finished products. Thus the use of Cleaner Production – P + L can be inserted in this sub – area . Thus , the expected production processes and logistics support to be generated less waste , ie , there is a pre- production planning so there is less waste and tailings, and , moreover , seeks to schedule the use of materials in production and logistics processes that are less harmful to the environment and easier to recycle and decompose in the environment . Moreover , also in this sub – area can be studied using the waste incineration for energy to be consumed in production processes and use of technologies that deliver the energy and water onsumo.

The logistics distribution or exit ( outbound ) involves the relationship between the company and its end consumers and covers mainly the activities of storage, handling and transport. Accordingly , the installation of warehouses in strategic locations to reduce the transit of products ; saving water in the process of recharging batteries for forklifts, truck washing , cleaning of pallets and floor , using fleets of vehicles with bio – fuels , alternative energy , hybrid, electric and control systems that have pollutants can be adopted to reduce the environmental impacts.

Finally , the complete reverse logistics logistics cycle , operationalizing the return of goods after-sales and post – consumption to the production cycle and / or business . Becomes apparent that the end of all logistics processes are carried huge amounts of discarded materials , whether industrial waste, packaging materials , products returned by customers using or unused parts due to maintenance of machinery , vehicles and equipment, office materials, among others.

These materials can not simply be disposed in landfills , especially considering what to Law 12,305 of the National Solid Waste – PNRS , enacted in August 2, 2010 and regulated by Decree 7,404 of December 23, 2010 . This law provides , among other things , about the obligation of reverse logistics system for manufacturers, importers, distributors, retailers, consumers in different segments, such as: tires, batteries, pesticides, lamps, lubricants and consumer electronics, as well as containers in general.

So when it adopts sustainable logistics in its four sub-areas: supply, production support, distribution and reservation, besides complying with the environmental laws are aggregated values of different natures:

- Economical as it reduces the use of natural resources; avoiding paying fines and paralyzation of operations due to legal penalties; obtains savings with the use of recycled materials and packaging and; obtains revenue from the sale of waste; increased revenue per cover a new slice of the market, the “green consumers”.

- Competitive, companies that adopt sustainable logistics differentiate themselves from competitors, in some negotiations, especially in international markets, the inclusion of environmentally sound practices are predominant factor in negotiations

- Corporate image, companies that include sustainable logistics processes in your business strategy earn positive points in your image when considering consumer perceptions. Many consumers called “green”, environmentally responsible companies prefer those that are not, often agreeing to pay more for environmentally friendly product or service.

- Environment, including sustainable logistics in its business the company contributes to the maintenance and preservation of the environment and resources for future generations.

It is also worth mentioning that currently companies no longer compete individually between but between supply chains. Thus emerges the concept of management of green supply chain, which goes beyond sustainable logistics, covering and aligning the processes of all companies involved in a given supply chain processes with environmentally friendly.

Source: World Logistics Magazine