The Warehouse Future

Until a few years ago the warehouses were treated solely as an “undesirable cost,” but increasingly become part of a comprehensive strategy for manufacturing, sales, marketing and finance.

The stores represent approximately 30% of total logistics costs, and their participation has been growing in recent years. In most cases, handling operations and storage of materials represent a cost equivalent to 1% to 5% of gross revenue, thus being one of the major costs of a company. Given its relevance in the representation costs and their role in streamlining the process of production or supply lines to approximate markets, it is vital to understand the role of the warehouse and the different ways to exploit their potential to add value to the supply chain.

The evolution of warehouses

Walked to the continuous evolution of warehouses both in their role and importance, as in their physical infrastructure. Completely understanding the dynamics of this change and the impacts on people – processes – triad technology will be crucial for enterprises to keep it highly competitive in their respective markets.

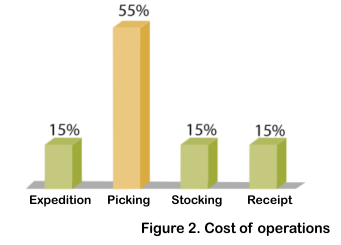

In the 60s, 70s and 80s, the warehouses were seen as merely accumulating material areas with little or no complexity. The buildings were simple, unsophisticated, being rare to find heights of more than eight meters, floors with high resilience (more than 6 tonf/m2), elevated docks etc..

From the economic stabilization achieved with the Real Plan in mid of the last decade, a major shift begins to occur in the behavior of Brazilian consumers. Gradually, we fail to make monthly purchases (driven by inflationary spiral) that supplied the larder of our homes and we buy less, but more times. That is, we become weekly visitors supermarkets increasingly attractive to consumers, the weekly specials and the numerous ” birthdays ” held throughout the year.

Fractionation of purchases by consumers caused a radical change in warehouses until then adapted to deal only with full loads and closed pallets. Right now, there is a need to “break ” large lots into smaller lots, in fractions of pallets, boxes and even in primary units. Hence arises the necessity of establishing the order picking area (or picking) and concern with the consolidation of loads in different types of vehicles.

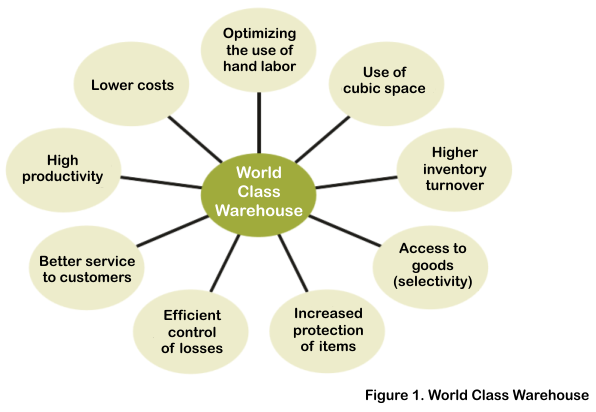

The picking activity is currently the most representative in costs among existing operations (Figure 2).

In this transition, the lodges attended the uprighting of the stocks, the use of specific equipment handling, the formalization of the processes and the specialization of hand labor.

One last wave has been experienced since the turn of the century, with the adoption of new information technologies (in particular systems WMS – Warehouse Management System), automation of handling and storage of materials management through performance indicators (KPI – Key Performance Indicators) and incessant housekeeping practices.

The new warehouse, renamed the Center for Logistics Services, take on new tasks and become like mini-factories, working intensively in the assembly of promotional kits, specialty packaging, palletizing and repaletização etc.. In this new reality, which enters the warehouse is not necessarily the same as what comes out.

In new stores, more than simply storing materials, there is a concern with the physical flow of materials and information.

The new warehouses go to streaming operations, with fewer and fewer stocks, very close to the cross-docking operations, detailed below.

Figure 3 illustrates the process experienced by the stores over the last 30 years.

The cross-docking operations

Cross -docking is a distribution operation in which the products are received, selected and sent to another vehicle, and therefore requires great accuracy as to the time of entry and exit of products.

Besides eliminating the high costs of handling products, investing in stocks is substantially reduced by eliminating multiple storage locations.

Cross-docking operations lead to a reduction of 30% compared with a conventional operation in which the stock formation occurs.

A, though simple in theory, cross-docking operation is very difficult to achieve in practice. Some operating conditions must be met:

- The target location is known of the material upon receipt;

- Your client is ready to receive the material immediately;

- Product in their docks is pre – labeled;

- Needs of quality control must be minimal;

- Preferably operation with full pallets;

- There is enough space near the docks;

- Deliveries disciplined in the warehouse.

Are good candidates for cross-docking operations involving seasonal items and items with high sales volumes.

The physical infrastructure of warehouses of the future

Very different from today, the stores of the future will combine its traditional role in storage, but should also facilitate the rapid flow of materials at the entrance (inbound) and outgoing (outbound). This processing capacity (throughput) will be vital to distribution operations.

As feasible as antagonistic functions in one physical structure?

The discussion begins by the size of the warehouse. U.S. studies show that the warehouses that have better performance indicators are among ten thousand m2 and 30 000 m2.

Control problems tend to increase with the size of the warehouse.

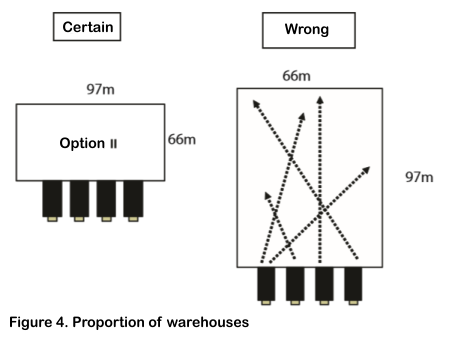

In large warehouses, productivity is hampered by excessive movement due to large distances and poor visibility of the workflow. The difficulties in communication and supervision can possibly counterbalance the savings from large volumes of application or through high levels of mechanization. Also important will be properly gauge the size of the store, looking for a suitable ratio between length (face where the docks are located) and width of the warehouse (Figure 4).

The docks and areas of stage will play a key role in this new warehouse, in which prioritize the flow of materials and not their storage.

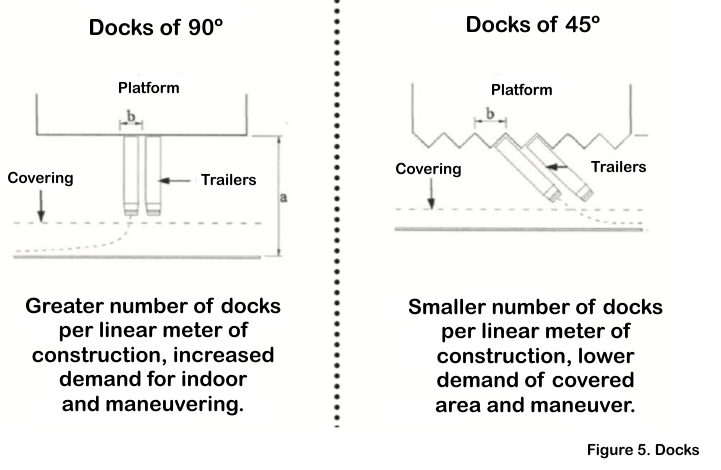

The dock is the means by which a vehicle is placed in the warehouse for loading and unloading. There are two basic types of settings docks for trucks: 90 th and 45 th. The dock 90 have smaller width and larger than the depth dock 45. Consequently, the dock 90 needs less space inside the warehouse and more space outside it, for the execution of maneuvers. The greater the width of the dock, the greater the internal space dedicated to each warehouse dock. Therefore, docks 90 are used more than inclined.

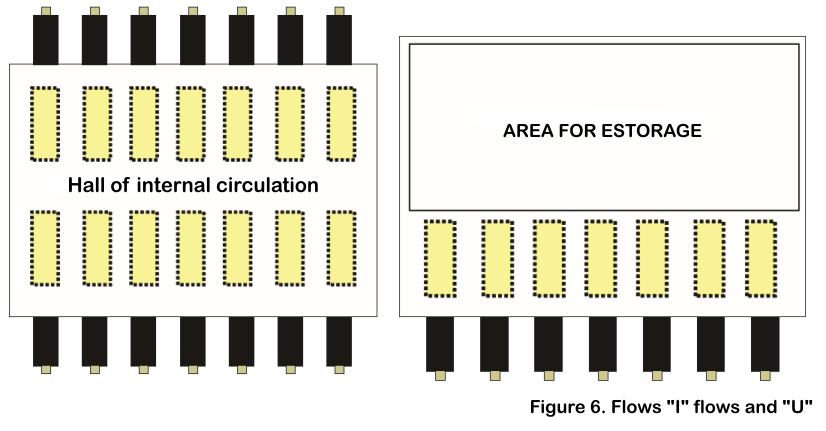

The location of the docks used will depend on the operational layout, stream “I” flow or “U”.

Flows in ” I”, or flows through the warehouse, are more common in cross-docking operations on large carriers (terminals) and usually do not have areas for storage.

Flows in a “U ” are commonly used by industries and retailing.

Flows in the form of ” U” bring great advantages over other types of project:

- Excellent utilization of the dock (equipment, staff, etc.)? due to the fact that the process of receiving and shipping can share the dock doors;

- Facilitating cross-docking, as the shipping and receiving docks are adjacent to each other;

- Optimization of forklifts because the travel storage and removal are easily combined and storage locations closer to the docks are the natural locations of items of higher turnover.

The amount of docks, traditionally sized in proportion to a dock every thousand m2 of constructed area, will change radically. Will be necessary to have at least one dock every 500 m2 of covered area built.

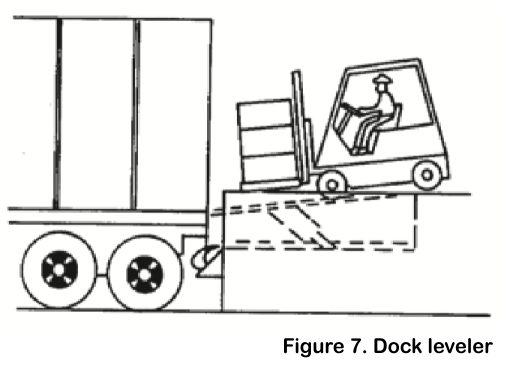

The docks will be equipped with equipment for leveling (dock leveler) warehouse with trucks, since there is no standard height vehicles. These facilities provide loading and unloading faster and safer.

In addition, each existing dock should be internally an area of stage (waiting) corresponding to the size of the vehicle load/unload used (8.0 to 15.0 meters long, 2.5 meters in width).

The size of the areas of stage- in/stage -out is directly related to the types of operation receiving and shipping:

- A high degree of checking and inspection will increase the need for space;

- In case of impossibility of control over the arrival of the vehicle (dock schedule), a sufficiently large area must be designed to withstand the ” peaks ” operating throughout the day;

- Receipt of bulk cargoes require palletizing materials before storage;

- Cross-docking operations require separation and consolidation of loads.

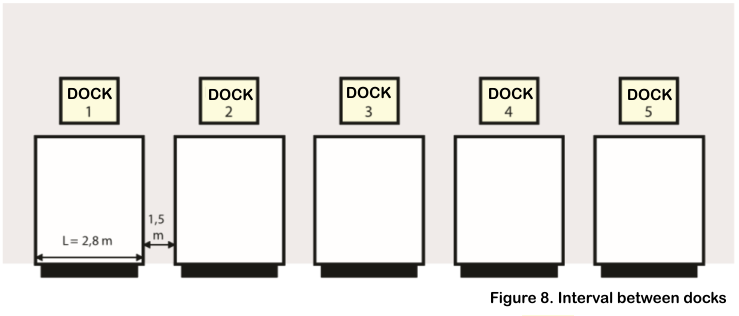

Among the docks should be an interval of 1.5 m to 3.0 m, depending on the equipment used for moving between stages.

Trucks should enter the receiving dock or shipping in a counterclockwise direction so as to allow the defendant to enter the dock clockwise. This will facilitate the operation for the driver, who will be guided by your mirror, not the mirror located on the passenger side door.

The external areas, consisting of the courtyard for maneuvering and parking of vehicles and streets for circulation thereof, will also have a key role. Usually forgotten or undersized, will have important role, mainly to enable operations with high concentration of movement in the last week. The depth of the yard shunting vary from 12 m to 20 m, depending on the length of the truck.

As for the vertical integration of inventory, the traditional door – pallet structure commonly used by businesses, and often regarded as the best and perhaps only solution, give space to a study of cubic optimization, involving the analysis of various solutions that address differently with the question of density, selectivity and speed of processing. The best solution will be a mix of solutions and not just door – pallet solution.

WMS – Warehouse Management System

Not everyone needs to have a WMS system. Surely any logistics operation will benefit from the use of this important tool, but you need to assess the costs of the acquisition and deployment of the system, compared with the benefits to be obtained.

The WMS is a robust and complex tool requiring huge initial efforts, especially with the parameterization of the system and the constant maintenance of the same, who shall ensure its smooth operation. Defenders argue that WMS systems:

- WMS will reduce inventories;

- WMS will reduce the cost of hand labor;

- WMS will increase the use of storage capacity;

- WMS will increase customer service;

- WMS will increase the level of accuracy of inventories.

The implementation of WMS, associated with the automation of data collection, actually lead to greater accuracy of information inventory, reduced labor workforce and a greater capacity to better serve their customers, by reducing the times of cycle. Expectations regarding inventory reduction and better use of the cubic space available are not always true.

Despite the benefits that may be achieved by the reduction of hand labor, the decision to invest or not in a WMS system will be directly subject to the level of service required by their customers and the ability to fill gaps and add system value.

With a good WMS system, you can, for example, practice FIFO (First in, first out), conduct cross-docking, meet emergency requests, reduce stockouts, significantly reduce the risk of obsolescence of inventories provide information on time real etc..

Carrier Logistics is an essential tool. For Shippers, should be carefully assessed, taking into account technical and financial aspects.

Once decided on the deployment, it is necessary to take an earlier step: optimization of existing physical infrastructure and review of key processes. Without it, will automate what is bad, so we will have many difficulties in obtaining the expected benefits.

The next big challenge of warehouses

The advancement of reverse logistics will become the next big challenge for professionals warehouses. Discards, still unrepresentative and treated with certain disregard, greater focus on businesses.

Areas today intended for receiving, inspecting and sorting the materials, even negligible, will be resized to allow the correct destination of the material returned, whether restocking, reuse of components, scrap etc..

A new reality, in which the reverse logistics becomes representative in values and volumes, forget the FIFO (First In, First Out) and understand how FEFO (First Expired, First Out) works.

Conclusion

The best storehouse is, without doubt, one that does not exist. But, despite efforts in the integration of materials, ECR chain (Eficient Consumer Response), Just- in-time and Quick Response, the chain of materials will never be so perfectly coordinated to the point of eliminating the handling and storage activities altogether.

So if the warehouses can be considered a “necessary evil “, then we need to learn to live with them and extract the best possible, either in performance or operating costs.

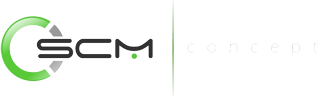

A systemic view, involving people, processes, technology and infrastructure will be essential to achieving a world class performance in handling and storage of materials operations.

Source: World Logistics Magazine