The value of outsourcing logistics

The reason for the existence of outsourcing is economically viable acquisition and short-term expertise and access to the use of the assets and technology to perform the services, benefits and cost-sharing. As in other segments, the increased complexity of operations and resources challenges the ability of the contractor to account effectively service through investment in resources and management, and in short time, to remain competitive in your market and avoid the risk of collapse in their logistics operations.

The outsourcing contractor diverts investments in recruiting and staffing, spending for the acquisition and maintenance of assets and training systems, and management of all this property. And gives instant access to years of diverse experience, a number of selected and integrated professionals, mature and equally integrated systems, and best market practices.

The idea is good, obvious, but of course that only works if the provider really deliver on their part effectively, adding to the operations of the above ingredients. A judicious choice and within the spectrum of providers actually qualified to service type game avoids these risks and ensures a sufficient level of capability, quality and performance.

By the contractor, this decision implies maturity and competence in the subject, this competence not focused on running, but to understand and monitor the provider, calibrate expectations and ensure your part for the performance of services satisfying the needs of the business. In fact, from the correct choice of provider, such management is exactly what makes the difference in the results to be obtained.

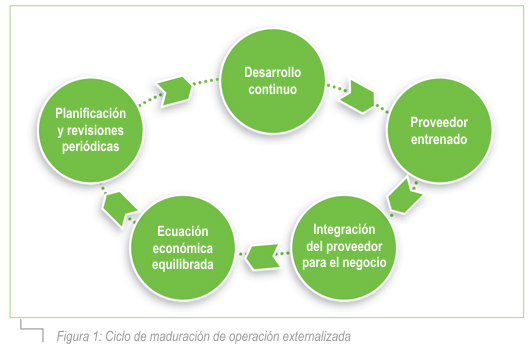

For a successful partnership, some factors are crucial:

• The chosen provider must be able to integrate the business process and the contractor to perform his part in keeping the content, speed and flexibility with it. Must understand the functional structure of the contractor and the operation of the business and the market served by it.

One example is to realize that, for 2012, many contractors are reducing their volume forecasts marked by disappointment with the previous year, but will require quick reaction from their providers when consumption prove more robust and economically well-founded than in 2011.

• The provider must have sufficient size and height and the running of the service experience. Following some crucial features to the performance, flexibility and ability to deal with ups and downs just comes with the size, experience and resources of the operator.

• The economic equation of the partnership must be suitable for both parties. It is up to the contracting officer to identify the right balance between price and value, avoiding trends simplistic trading at lower prices that threaten this balance. The ideal point occurs when the logistics costs to the contractor is within acceptable parameters in your budget, while the provider can make the margin that pays your business.

• The planning and delivery of services should be integrated into the activities of S & OP (Sales and Operations Planning), promoting the access provider to demand planning. This factor includes the integration of provider, logistics manager and business development areas. This integration is not common to find, but it makes much difference and eliminates many conflicts and weaknesses in information circuits. It helps if managers and sales agents have a minimal notion of the magnitude, complexity and logistical behavior of your market. Customers contractors also have their complexities and inconsistencies of structure and internal conflicts that directly reflect on their participation in the logistics process.

• The hiring manager must keep himself and his team in an attitude of sincere partnership, mutual trust and eliminate any trace of conflict management by, dodging a poor relationship Customer Supplier x, based on charges, accusations, defensiveness and penalties. The frequent use of such devices as policies of liens and other bonuses and penalties in contracts assume that poor relationship between the parties and encourages everyone involved in the opposite sense of real partnership.

A balanced economic equation does not need bonus, and deteriorates burden.

• The provider must give the best to the performance of the business and the conduct of business in mind, avoiding summarize their work to the simple service requests on the operating front, or contracts, and SLAs. Must also balance the attitude of serving with submitting, maintaining proper posture you would expect from a specialist, leading the customer himself to follow and understand your reasons, difficulties and opportunities where and when needed. If the provider submits to all requests from the contractor, indiscriminately, lost its role as expert and the economic and operating balance of the project, leading to recurring conflict and the potential deterioration of the relationship and performance.

Establishing and maintaining the right balance between serving and submitting is a subtle art that needs to ensure that the customer is driven by the influence best solution on a voluntary basis, as is served in the most complete, robust and enduring way.

• The service must be monitored closely and down the integrated team between provider and contractor, through monthly review of indicators and the number of operation, continuously improving the content and significance of such information. These are moments of integration and promotion of authentic synergy, enhancing the effective range of performance excellence. This factor reaches excellence when both contractor and operator, invite the client to the contractor participate and contribute to this compound.

• These teams, involving minimally, on the provider side, Operations (Warehouse and Transportation), Engineering, Cost Analysis, Human Resources, Information Technology, and the contractor, the manager and staff, a commercial area and Relationship with customers and Finance, should be recurrently involved in the continuous improvement process, sharing productivity gains in a structured way.

It is highly recommended that there is always a professional, comprehensive, contract the correct legal terms, which clearly contains all the conditions of the relationship and all commitments, not to depend on situational and temporal interpretations of those applied to its management, which may change over time. And this contract must have explicit conditions required service level (SLA). This basic requirement is already involved when companies are multinational or national publicly traded, more advanced in the category of Corporate Governance.

The forecast for long-term relationships – minimum contract of three years or more, renewable for equal periods – are more productive because they allow long-term planning, with clarity and firmness so that the provider makes investments and optimize their funds invested with ensuring economic returns in the medium to long term. For the contractor, the obvious benefit is to enjoy the progressive knowledge of the provider about your business and behavior, and the domain of the needs of the operation and its variations. And avoids the costly periodic changes, making their productivity back to zero.

Often happens that in Procurement contractors make checks market prices, and get different results from those in practice with your provider often lower. This practice does not necessarily mean that the current provider is expensive, but he intimately knows the operation and their actual costs. As an operation that consideration to price it, nothing replaces the continued experience with the operation to understand their true relationship between cost and value, and between flexibility x average activity. It’s a tactical mistake to let this simplistic approach usually results in a traumatic and damaging to the logistics process change.

Current state of logistics outsourcing

Logistics cost is, it is a necessary evil. This concept is often the starting point for business managers, who look as if their own logistics looked Information Technology for decades, condemning this service to a level of management and insufficient resources to effectively contribute to the mission of the business. Fortunately, there are already positive benchmarking causing the evolution of this concept.

Outsourcing is not unanimous in logistics activities. There are still many companies, even large, including its focus on an immense effort to increase its efficiency in storing and distributing their goods, often with much larger teams than necessary, or with smaller teams, but with poor performance. And restricting the use of technology and equipment, the economic infeasibility and these investments are not the focus of the business. In accounting service costs for comparison with outsourcing, are usually left out overhead costs and shared services, which serve the operation as a whole. And are not considered the cost of doing it all at home you expect to obtain the third-party provider.

It is often observed that those who study outsourcing tends to compare the costs of current services with the cost of outsourced services and enhanced with higher levels of requirement. Generally, the projection does not take much of the current level of services desired performance cost.

There are also companies that are in the opposite direction, ie, leaving stable and economical outsourced arrangements for costly internal arrangements and starting almost from scratch in knowledge and experience. They possibly return to the services market, but after going through a troubled phase of logistics performance, and the effective recognition of all costs involved.

But there are also organizations that already have maturity in hiring logistics services, with teams and managers trained for this task. Providers who work for these companies achieve levels of productivity and higher, stable and faster performance. In search of such maturity, some have undergone renovations in its staff of professional management applied to this, in natural evolution and greater demand management process. It is true that part of this musical chairs still have more to do with addiction to blame and condemn the internal logistics professionals, but as in every case there must be an intelligent evolution.

It’s coming slowly, the providers and contractors are aware that outsourcing is how the displacement of a bodily functions out of the body, and involves keeping all nerve terminals attached to it, as if the body was still inside.

The practice of logistics outsourcing

By outsourcing, contractors may be coming from previous unsuccessful outsourcing or outsourcing for the first time. In both cases, though for different reasons, develop expectations for the provider that vary according to their degree of maturity.

At the higher end, there are those who know how to clearly express their needs, their limitations and weaknesses, their variations, etc.. Know exactly what the provider can do and what it is not certain that you can. Act in these cases allows the provider to achieve a full or even excess demand performance very quickly.

At the other extreme are those who attribute the previous provider the low performance of the operation, but, in fact, bring the new operation all real causes that led to the previous resident performance in your business process or its management, or the inadequate economic arrangement. In such cases, the provider must have the ability to correct those causes in a short time and allow the new operation or evolve born without deformities. Achieve excellence in these cases is slower, more turbulent and sometimes even impossible.

In general, a good logistics process is able to correct turbulence or shortcomings of the business and its relationship with the market process, but it has a limit. Where the contractor is undergoing profound changes and not yet mastered their business process, logistics pays a high fee for it.

Put a humorous but true form expectations about the provider does not have limits, and generally tend to demand everything at once:

• Maximum flexibility to withstand high and low demand of any magnitude;

• Absorb emergencies and last minute changes (or last minute);

• Cost (much) less than the in-house;

• Use fewer people;

• Move quota for other clients in peaks;

• Achieve performance indices near 100% in all aspects;

• Conduct activities in throughput times too short;

• Have a contingency plan for each and every event;

• Absorb cost increases without transfer prices;

• Fully meet any and all technical, operational standards, sustainability, etc.., Even those who own the contractor can not meet.

Briefly, to outsource many contractors try to put into practice all your desires performance not achieved internally or in the previous step. The expectation is that by hiring an expert, everything tends to change instantly.

Many of the expectations listed above are legitimate, each in its degree. The use of multi-client operations, for example, allows real flexibility, though limited by the individual characteristics of seasonal and mix. In dedicated operations, however, there is a tendency to persist some of the expectations apply in the former case.

The ideal equation derived from a mature and integrated understanding, with substantial commitments from both sides as premises the level of expected performance.

The basic representation of a successful outsourcing is the fulfillment of socio-economic process of receiving, storing and distributing goods to the final destination at the right time at the right cost. The good news is that this process not only occurs with reasonable performance if the provider is actually very unprepared, or business process outsourcer is very confusing and inconsistent. In an effort to discuss SLAs, KPIs and manage conflicts of business relationship with its customers, many contractors lose the reference and discuss the operation with a dramatic approach, while enjoying the comfort of a socio-economic process fully underway. This is not always realized.

Most often, problems and conflicts between contractor and provider are located in the flow of information, or in restricted portions of the operation as a whole. Or covering larger share, but for a limited time (conditions or occasional occurrences).

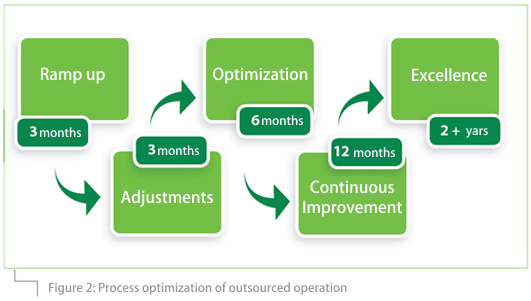

Projects usually are implanted in such a short period as three months if everything there been prepared properly. And the fullness of the operation, with first-line providers, arriving between six months and one year. Within two years, the operation must now be fully mature and productivity-enhancing process. Thereafter, the pursuit of excellence is a natural, quiet and effective process.

In fact, logistics is not uncommon for operations fail to exceed the initial stages without sequelae that threaten the future.

The practice of outsourcing is a relatively new process in Brazil, and is known the ongoing process of learning, both on the side of the providers and contractors, or shippers, as they are commonly called. Acting with an organ outside the body is not easy, as it is not easy being an external organ of a body in motion.

Source: http://www.tecnologistica.com.br/